Wallstarters & Ties

Wall Starter systems and ties join new walls to existing masonry, suitable for both internal and external brick or block walls. Timber Frame Ties suitable for tying masonry outer cladding to softwood structural framework.

Wall Starter systems and ties join new walls to existing masonry, suitable for both internal and external brick or block walls. Timber Frame Ties suitable for tying masonry outer cladding to softwood structural framework.

Helical Bar is used in general for crack stitching and reinforcing masonry in both new and existing masonry structures. Wall ties to bind the outer leaf of a wall to the structural wall.

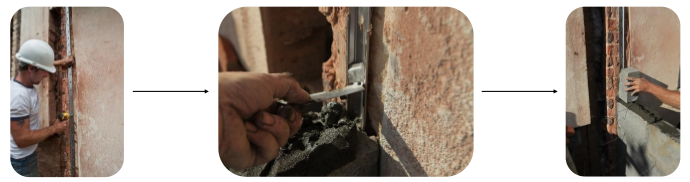

Traditionally tying a new wall to an existing wall this was done by toothing out method - removing alternate bricks or blocks to leave a tooth like shape, to which the new wall is tied. This process is time consuming and labour extensive, therefore more costly than the modern tying methods.

The wall starters are much easier and quicker to mount, reducing construction time and the cost. It also eliminates the problem of achieving adequate mortar bond at the toothed connection. The wall starter connector is simply bolted to the existing wall and wall ties are then slotted into the rack at distances, where it is required to tie into the new wall. The bond is just as strong as the traditional toothing out method.

Stainless steel wall starter systems join new walls to existing masonry, suitable for both internal and external brick or block walls. The connectors can be slotted together up to a maximum of 8 metres or 3 storeys high, from 60 to 250mm thick. One kit has two 1200mm lengths. Available in Austenitic Stainless Steel (Grade 304) and in Ferritic Stainless Steel (Grade 430).

Fixing instructions

- Plumb the lower connector against the existing wall so that it will be central to the new wall.

- Mark the position of the fixing holes. Each connector should be fixed at three points, the first and last slot and in the centre.

- Ensure that one fixing is at the point where the two connectors slot together and overlap. Fixings should be into brickwork and not mortar joints. Drill and plug using an 8mm masonry drill bit. Fix the bottom two holes lightly using the stainless steel coach screws and washers.

- Slot the upper connector into the lower one and repeat the above stages. The upper connector can be cut to length if required.

- Tighten all fixings using a 10mm socket or box spanner.

- Build wall in the conventional way with a full mortar joint between the existing and the new wall.

- Ties should be inserted at a maximum of 300 centres, every third brick course or each block course.

- Ensure that the ties and connectors are completely embedded with mortar.

- When using in external walls, ensure that the bottom edge of the connector is above the damp-proof course and that a weather seal of approximately 10mm should be created between the connector and the existing wall using a flexible mastic sealant or a compressible sealing strip.

Starter Ties are used where new walls are being built directly from existing brickwork. Sizes 150mm and above have a drip feature for use where there is a cavity and a new wall needs to be built. Available in 130mm, 150mm, 180mm, 200mm, 225mm and 275mm.

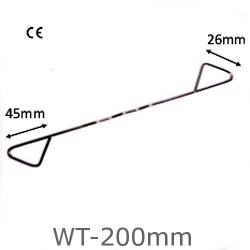

Stainless Steel Light Duty Ties offer a practical and cost effective solution for masonry cavity walls in box form domestic dwellings of up to two storeys or a maximum 10m in height. Available in 200mm, 225mm and 250mm. Used for cavities from 50mm to 125mm.

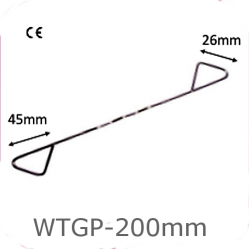

General Purpose Stainless Steel Housing Ties offer a practical and cost effective solution for masonry cavity walls in domestic houses and small commercial buildings of up to three storeys or a maximum 15m in height. Available in 200mm, 225mm and 250mm. Used for cavities from 50mm to 125mm.

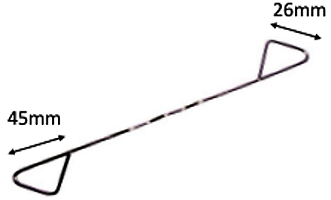

Stainless Steel Double Triangle Tie is the traditional wall tie that offers a practical and cost effective solution for masonry cavity walls in domestic houses and small commercial buildings of up to three storeys or a maximum 15m in height. Used for cavities from 100mm to 125mm. Housing Ties meet the requirements of Part E of the Building Regulations for Type A in party walls of any height. Available in 250mm lengths.

Timber Frame Ties are suitable for tying masonry outer cladding to softwood structural framework of domestic dwellings and industrial/commercial buildings up to 4 storeys and not greater than 15m in height. Suitable at a density of 4.4 ties per square meter for buildings anywhere in the South East of England where basic wind speed does not exceed 44 m/s and for buildings on town and city sites in areas where the basic wind speed does not exceed 52 m/s. In more severe situations the tie density should be increased to 7 ties per square meter. Available in 50mm, 75mm and 100mm.

Movement Ties are designed to provide restraint in one direction and movement to allow for horizontal expansion and contraction. The Debonding Sleeve is located over the embedment detail to allow the tie to move. Typical usages are in areas where masonry is restrained to Steelwork columns and in long spans of brickwork where movement joints are required.

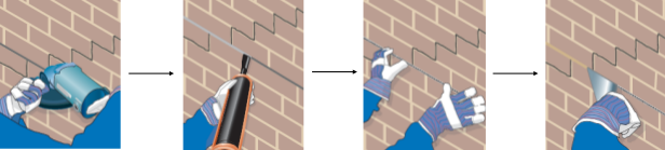

Helical Bar is used for crack stitching and reinforcing masonry in both new and existing masonry structures. Available in 1 and 2 metre lengths. The deformation of the fins makes the bonding characteristics of the Helical Bar far superior to alternative standard reinforcing materials. Made from stainless steel grade 304.

- Rake or cut slots into horizontal mortar joint to a depth of between 25-35mm and a 450mm or 6 brick courses vertical spacing.

- Vacuum out the slots and thoroughly flush with water.

- Mix the two part Grout (HG3) in the tub provided.

- Insert a bead of Grout into the back of the slot using a grout gun.

- Push the Helical Bar into the Grout to obtain good coverage.

- Insert a bead of Grout over the exposed Helical Bar and iron into the slot using a finger trowel.

- Fill in the slot with Grout leaving sufficient depth for re pointing.

- Use a colour matched mortar to repair fractured bricks.

- Re-point the slot to match existing as closely as possible and make good the area.

- If in doubt, seek advice from a structural engineer.